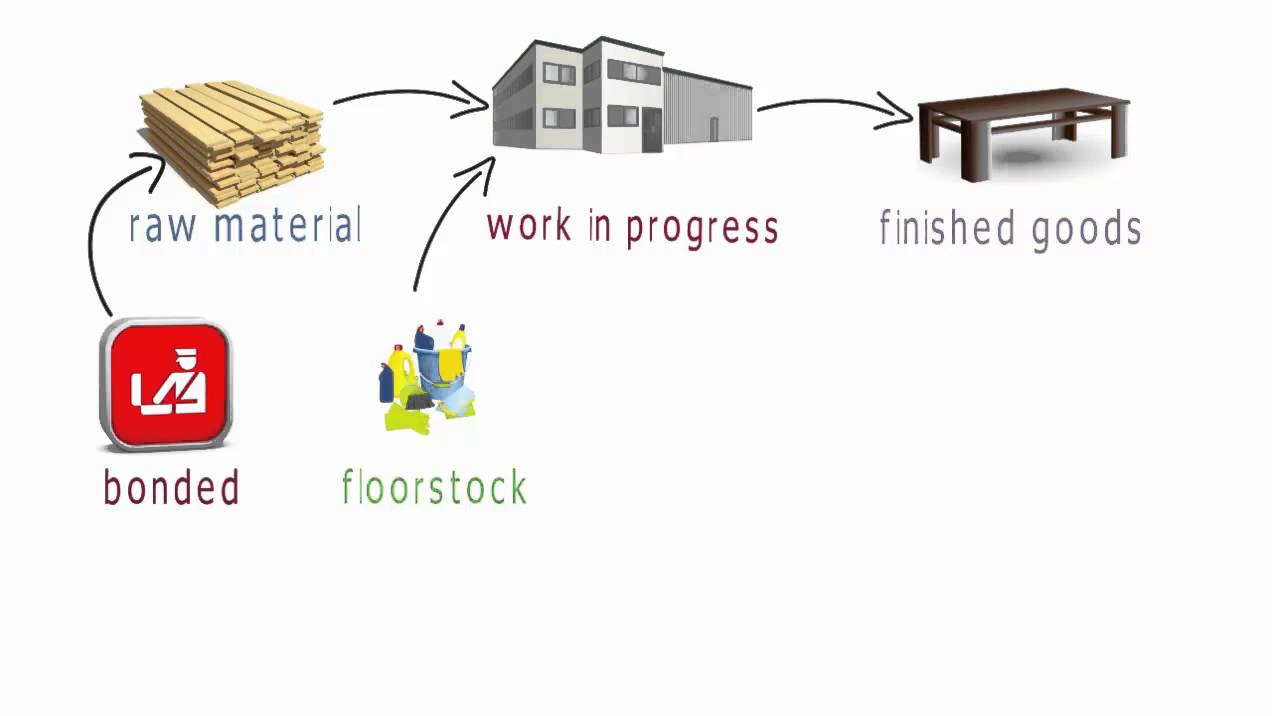

Having a decoupling inventory can reduce any bottlenecks and decrease the odds of production stopping completely. This type of inventory includes any items you use during the production process that aren’t part of the finished product. For example, any supplies and equipment necessary for maintenance, repair, and operations, including safety equipment, repair supplies, and office supplies. There are many different types of inventory that move through the process, from raw materials to works-in-progress and, finally, a finished product.

Leveraging Automation Tools

Theoretical inventory is the amount of inventory that a business should have on hand based on its sales history and forecasting data. Theoretical inventory is a valuable tool for businesses to use when planning their inventory levels. However, it is important to note that theoretical inventory is just a model.

Raw materials

Maintenance, repair, and operating supplies—or MRO goods—are items put in place to maintain tasks in the production process. These goods are usually a major component of the production process but are not directly a part of the finished product. Despite these differences in activity and production time, manufacturers can maintain the workflow by holding decoupling inventory in stock. In a manufacturing environment, very rarely does every machine produce at the same rate. One or two pieces of equipment may run several times faster than other pieces of equipment in front of or behind them in the production chain. Primary packing material includes the box, bag, or other material that encloses your product while on retail display.

- Leveraging advanced forecasting tools, such as analytics and machine learning, allows companies to predict demand changes accurately and adjust inventory accordingly.

- AI analyses extensive data sets to uncover patterns and trends, enabling smarter inventory decisions, while machine learning continuously improves forecast accuracy based on new data.

- WIP inventory examples could include suit pants that need to be sewn together or coffee beans that have been roasted and are waiting to be ground.

- Transit inventories are crucial to businesses that need to transport items or materials from one location to another.

What are the different types of inventory?

Cycle inventories are usually materials which are directly used in the production or they are part of some regular process. That’s why tracking metrics like your inventory turnover is important for finding the right balance. Consignment inventory is a good option for businesses that want to sell a wide variety of products or that have a limited budget. However, it is important to note that consignment businesses have less control over their inventory level and profits. Dropshipping inventory is a low-cost and low-risk inventory model for ecommerce businesses.

A pen manufacturer will build up components, supplies, and completed stock in the months leading up to the start of a new school year (when demand is at its highest). Then, during the rush of back to school time, the manufacturer slowly reduces the excess inventory without having to increase production time. There’s a lot to keep up with when dealing with inventory, from keeping the right inventory quickbooks online login levels to overseeing production standards to analyzing demand. If you want to properly fulfill clients’ orders and stay in a competitive market, there are some inventory management strategies you can follow. Work-in-progress (WIP) inventory includes unfinished products currently being manufactured. Think of WIP inventory as all materials that have been worked on but aren’t completed yet.

What is inventory? Types and examples

Through blockchain, businesses can track inventory with precision and ensure ethical sourcing, enabling quick adjustments to shifts in demand or supply. With optimised stock levels, businesses can consistently meet customer needs, offering quick delivery and reducing out-of-stock situations. This reliability builds trust, driving customer loyalty and enhancing lifetime value through positive experiences. Inventory that is being worked on is Work-In-Process (WIP), just like the name sounds. From a cost perspective, WIP includes raw materials (plus, sometimes labor costs) that are still “in production” when the accounting period ends.

VMI, or vendor managed inventory, is an agreement between a buyer and a seller where the seller manages the buyer’s inventory for them. Unlike its brothers and sisters, anticipation inventory trafficks in the foreseen, the … anticipated! It refers to extra inventory kept on hand periodically or seasonally to account for known fluctuations in demand. The holidays are a great example of this, as many businesses factor in holiday shopping into extra inventory.

In manufacturing, inventory consists of in-stock items, raw materials and the components used to make goods. Manufacturers closely track inventory levels to ensure there isn’t a shortage that could stop work. Inventory encompasses all items a business holds, from raw materials required for production to the finished goods inventory ready for sale. Finished goods inventory is the inventory that is ready to be sold to customers.

Wherever you land on the inventory management spectrum, all manufacturing businesses use common inventory types to identify their stocks. Manufacturing inventory follows the manufacturing process, starting with raw materials, then moving to work in progress, and finished goods. Effective tracking of raw materials inventory ensures enough raw materials are on hand to meet production schedules without overstocking, which can tie up cash flow and increase storage costs. Inventory represents one of the most valuable assets for any business, particularly within manufacturing and supply chain management. Essentially, inventory refers to all the items and materials a company holds, ranging from raw materials awaiting production to finished goods ready for sale.